Introduction

The solar industry is a rapidly evolving landscape, with new technologies and innovations emerging at an unprecedented pace. One of the most anticipated events in this sector is the RE+ Trade Show, a platform that brings together industry leaders, experts, and enthusiasts to discuss the latest trends and showcase cutting-edge products. This year, Metroll, a renowned name in the construction and solar industry, is set to make waves at the event with its groundbreaking purlins designed specifically for the solar industry.

About RE+ Trade Show

The RE+ Trade Show is an annual event that serves as a hub for the solar industry, attracting a diverse audience ranging from manufacturers and suppliers to policymakers and researchers. The event features a variety of exhibitions, panel discussions, and workshops, all aimed at fostering innovation and growth in the solar sector.

Metroll's Participation

Metroll has been a pioneer in the construction industry, offering a wide range of products that include roofing, fencing, and structural components. This year, the company is stepping into the limelight at the RE+ Trade Show to present its latest offering: specialized purlins for the solar industry.

Why Purlins?

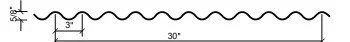

Purlins are horizontal beams that provide structural support to roofing or wall cladding. In the context of solar installations, purlins play a crucial role in ensuring the stability and efficiency of solar panels. Metroll's purlins are designed to offer enhanced durability, ease of installation, and cost-effectiveness, making them an ideal choice for solar projects.

Features and Benefits

Durability: Made from high-quality materials, these purlins are built to withstand extreme weather conditions.

Ease of Installation: The design incorporates features that simplify the installation process, reducing labor costs.

Cost-Effectiveness: By optimizing material usage and installation time, Metroll's purlins offer a cost-effective solution for solar installations.

Visit Us at Booth #23108

We invite you to visit Metroll's booth at the RE+ Trade Show to experience these innovative purlins firsthand. Our team of experts will be available to answer any questions and provide detailed demonstrations.

Conclusion

The RE+ Trade Show is a golden opportunity to explore the latest advancements in the solar industry, and Metroll's participation promises to add significant value to this event. With its specialized purlins, Metroll aims to set a new standard in solar installations, offering a blend of durability, efficiency, and affordability.

We look forward to seeing you at the RE+ Trade Show!

#Metroll, #REPlusTradeShow, #SolarIndustry, #Purlins, #Innovation